Laser welding and cutting technology

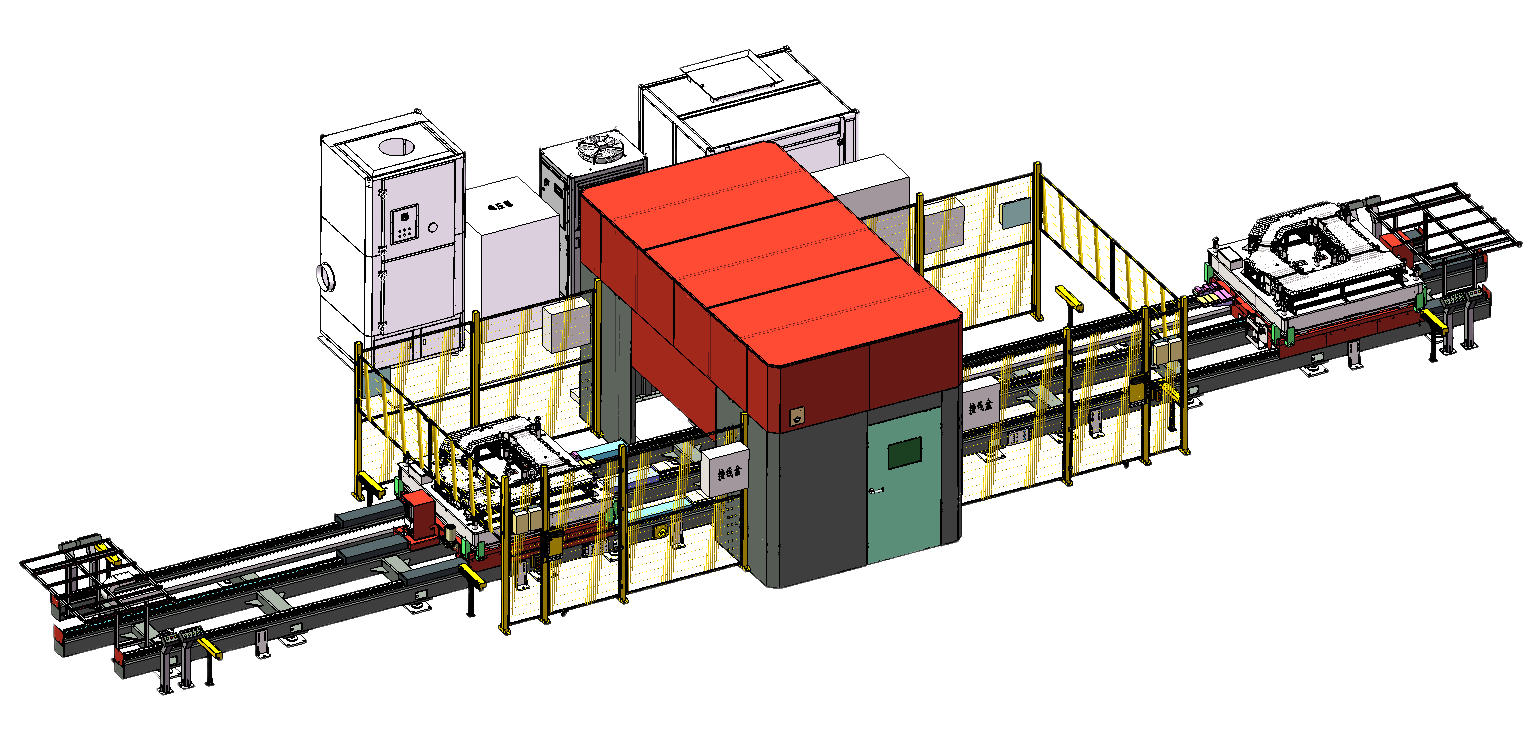

As an efficient and high-precision processing technology, laser technology plays an increasingly important role in industrial production. Especially in the field of laser welding and cutting applications, its advantages are highlighted, for customers to reduce costs, improve efficiency, combined with vertical intelligent deep plowing automation industry, in the application of laser welding and cutting technology in industrial production, the design of the best solution.

Application of laser welding and cutting technology

Save input of raw materials and mouldsLaser welding and cutting technology can accurately control the processing process, reduce the waste of raw materials, avoid the large molds used in traditional processing, and save production costs.

Reduce customer costs: Through the application of laser technology, companies can improve production efficiency, reduce labor costs and waste, thereby reducing the total cost of product manufacturing and providing customers with more competitive product prices.

Realize the later automation expansion functionLaser technology has the characteristics of digital control, which can be combined with the automatic production line to realize the later automation expansion function. This provides convenience for the future production line upgrade and intelligent development of enterprises.

Advantages of laser welding and cutting technology

High precisionLaser technology has very high processing accuracy, can achieve micron-level processing, suitable for industries that require high precision parts.

High SpeedLaser processing speed, can achieve fast and efficient production, improve production efficiency, shorten the processing cycle.

non-contact machining: Laser processing is a non-contact processing technology, which avoids the contact process that may cause deformation or damage to parts in traditional processing, and ensures the processing quality.

Small thermal impact: The heat-affected area during laser processing is small, which can reduce the risk of thermal deformation of the material, and is suitable for processing scenarios with high requirements on material performance.

Future development of laser welding and cutting technology

With the development of industrial automation and intelligence, laser welding and cutting technology will be further integrated into the production line to achieve full digital control. In the future, laser technology may be applied in more fields, such as 3D printing, laser cleaning, etc., bringing more innovations to industrial production.

As an efficient and high-precision processing technology, laser welding and cutting technology has brought great advantages and opportunities for industrial production. Hezong Intelligent has the advantages of saving raw materials, reducing costs, high precision, high speed, non-contact processing, and small thermal impact on its design, which makes it widely used in various industries. With the continuous advancement of technology and the expansion of application fields, laser technology will continue to play an important role in promoting industrial production to a more efficient and intelligent direction.